Anodizing parts

Moderate Cost: Combines the cost efficiency of basic machining with the added value of CNC precision for customization. High Design Freedom: Allows for complex geometries and customized features

Advantages of CNC Processing Anodizing Parts

1.High Precision and Consistency

Utilizing advanced CNC machines ensures that each anodized part is manufactured with high precision and consistency. The computer-controlled processes minimize human errors, resulting in tight tolerances and repeatable quality.

2.Enhanced Surface Finish

Anodizing provides a durable and aesthetically pleasing surface finish. It creates a protective oxide layer on the surface of the parts, enhancing their corrosion resistance and wear resistance. The surface can also be easily dyed to various colors, offering a wide range of visual options.

3.Wide Material Compatibility

CNC processing can handle a variety of materials suitable for anodizing, such as aluminum and its alloys. This allows for the production of anodized parts with different mechanical properties and characteristics to meet various application requirements.

4.Customization and Complexity

CNC machining enables the production of complex shapes and intricate designs for anodized parts. The flexibility of CNC programming allows for customization according to specific customer requirements, making it suitable for both small batch and large-scale production.

Machining Process of CNC Processing Anodizing Parts

1.Material Selection

Commonly used materials for anodized parts include aluminum alloys such as 6061, 7075, and 6063. These materials offer good mechanical properties, corrosion resistance, and anodizing performance.

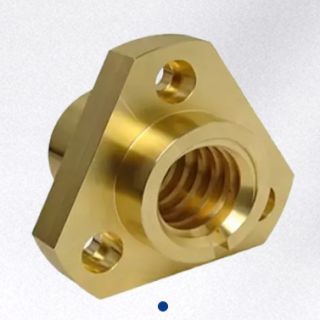

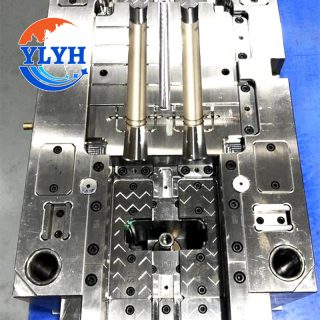

2.CNC Machining

The parts are first machined using CNC lathes or milling machines to achieve the desired shape and dimensions. The CNC machines follow precise toolpaths based on the CAD/CAM data to ensure accuracy and consistency.

3.Anodizing Process

After machining, the parts undergo the anodizing process. The process involves immersing the parts in an electrolytic solution and applying an electric current to form a protective oxide layer on the surface. The thickness and properties of the oxide layer can be controlled by adjusting the anodizing parameters.

4.Post-Anodizing Treatment

In some cases, post-anodizing treatments such as sealing or dyeing may be applied to enhance the surface properties or achieve desired colors. The parts are then inspected and tested to ensure they meet the required quality standards.

Applications of CNC Processing Anodizing Parts

1.Aerospace

Used in aircraft components such as engine parts, landing gear components, and structural elements. The high precision and corrosion resistance of anodized parts are crucial for the reliability and safety of aerospace applications.

2.Automotive

Applied in automotive parts like engine components, transmission parts, and body panels. Anodized parts offer durability and aesthetic appeal, contributing to the performance and appearance of vehicles.

3.Electronics

Found in electronic enclosures, connectors, and heat sinks. The good electrical insulation and thermal conductivity of anodized aluminum parts make them suitable for various electronic applications.

4.Consumer Goods

Utilized in consumer products such as furniture, sporting goods, and kitchenware. The attractive appearance and corrosion resistance of anodized parts enhance the product value and user experience.

Comparison with Other Surface Treatments

| Surface Treatment | Corrosion Resistance | Wear Resistance | Aesthetic Appeal | Cost |

| Anodizing | High | Medium | High | Medium |

| Painting | Medium | Low | High | Low |

| Plating | High | High | Medium | High |

| Powder Coating | High | Medium | High | Medium |

Packaging and Shipping

FAQs

Can all aluminum alloys be anodized?

Most aluminum alloys can be anodized, but the anodizing performance may vary. Some alloys may require special anodizing processes or may have limitations in achieving certain surface properties. It is important to consult with the manufacturer to determine the suitability of specific aluminum alloys for anodizing.

How long does the anodizing process take?

The duration of the anodizing process depends on various factors such as the thickness of the oxide layer required, the size and complexity of the parts, and the specific anodizing parameters. Generally, it can range from a few minutes to several hours.

What are the common defects in anodized parts?

Common defects in anodized parts include uneven coating thickness, surface stains, and pinholes. These defects can be caused by improper anodizing process control, material impurities, or inadequate pre-treatment. Strict quality control measures are essential to minimize these defects.

Can anodized parts be repaired if damaged?

In some cases, minor damage to the anodized surface can be repaired by re-anodizing the affected area. However, for severe damage or if the part's dimensional accuracy is compromised, it may be necessary to replace the part.

Is anodizing environmentally friendly?

Anodizing is generally considered an environmentally friendly process compared to some other surface treatments. However, the anodizing process does involve the use of chemicals and the generation of waste. Proper waste treatment and management are necessary to minimize its environmental impact.

Reviews

There are no reviews yet.