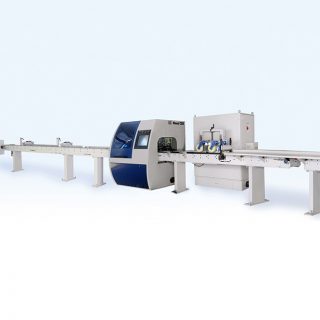

KOSO Valve Spray Painting Line

The valve spray painting line is designed for coating various types of valves, including ball valves, gate valves, and globe valves.

KOSO Valve Spray Painting Line

I. Introduction

The valve spray painting line is designed for coating various types of

valves, including ball valves, gate valves, and globe valves. The system

enhances corrosion resistance, prevents chemical media erosion, extends valve

lifespan, and ensures stable and safe industrial operation.

II. Application Areas

1. Petrochemical Industry

-

Used in oil extraction, refining, and chemical production to regulate fluid

flow, pressure, and direction.

2. Power Industry

-

Essential for thermal, hydro, and nuclear power plants to control steam,

cooling water, and other fluids.

3. Metallurgy Industry

-

Used in steel and non-ferrous metal smelting, where valves must withstand

high temperatures, high pressure, and corrosive substances.

4. Urban Water Supply & Drainage

-

Applied in municipal water supply, drainage, and wastewater treatment to

regulate water flow and pressure.

5. Shipbuilding Industry

-

Used in marine environments, where valves must endure high humidity and

salt spray corrosion.

III. Technical Overview

1. Basic Principles

-

The system utilizes automated or semi-automated processes to uniformly apply

protective coatings to valve surfaces, enhancing corrosion resistance, rust

prevention, and aesthetics.

2. Core Process Flow

-

Spray Booth

-

Enclosed structure with positive pressure air supply and multi-layer

filtration (primary, medium, high-efficiency filters) for a dust-free

environment. -

Explosion-proof design with VOC treatment systems (e.g., activated carbon

adsorption, catalytic combustion). -

Workpiece Conveying System

-

Custom conveyor solutions (e.g., overhead chains, roller beds, rotating

platforms) accommodate different valve sizes and weights. -

Variable-frequency speed control supports continuous or intermittent

operation. -

Intelligent Control System

-

PLC/Industrial PC centralized control with HMI (Human-Machine Interface)

for real-time monitoring of paint flow, pressure, and speed. -

Supports data tracking, fault diagnostics, and remote maintenance.

-

Environmental Protection System

-

Paint mist recovery system (wet curtain or dry filter) with 98%+ filtration

efficiency. -

Exhaust gas purification system (RTO, zeolite rotor) ensures compliance

with GB 16297 environmental standards.

IV. Technical Advantages

1. Superior Coating Uniformity

-

Precise atomization pressure and spray width control, preventing dripping,

orange peel effects, and defects.

2. Flexible Adaptation

-

Modular design, customizable for workpieces up to 30m in length and 50 tons

in weight.

3. Safety & Reliability

-

Explosion-proof electrical systems, gas leak alarms, and emergency stop

mechanisms ensure safety.

4. Eco-Friendly Design

-

VOC emissions <50mg/m³, meeting strict environmental regulations such as

China’s Air Pollution Prevention Act.

V. Development Trends

1. Larger Equipment for Large Workpieces

-

As valve sizes increase, spray painting systems must expand

accordingly.

2. Intelligent Automation

-

AI, robotics, and real-time monitoring improve precision and

efficiency.

3. Green & Sustainable Coating

-

Adoption of low-VOC, environmentally friendly coatings and advanced spray

technologies.

4. High Efficiency & Energy Optimization

-

Enhanced system design for better energy utilization and lower operational

costs.

Reviews

There are no reviews yet.