Shop

Showing 545–560 of 778 results

-

Contact Us

The 44221 outdoor leisure sofa series features beige cushions, brown twisted rope mesh weaving, and a white powder-coated aluminum frame, paired with a rectangular sintered stone coffee table. Perfect for extending indoor comfort into outdoor spaces.

-

Contact Us

The 43371 Series is a stylish and comfortable outdoor sofa set featuring thick round rope weaving in a sleek U-shaped frame. It includes a three-seater sofa, two single armchairs, and two round coffee tables of varying heights, perfect for enhancing garden or patio spaces with natural charm and modern elegance.

-

-

Contact Us

Albumin-bound paclitaxel takes the advantage of nanotechnology to combine the drug substance with human albumin to generate nanoparticles with improved solubility

-

Contact Us

Albumin-bound paclitaxel takes the advantage of nanotechnology to combine the drug substance with human albumin to generate nanoparticles with improved solubility

-

Contact Us

The panel load box is a kind of static load test for pile foundation, which is suitable for the bearing capacity detection of large-diameter and large-tonnage pile foundation.

-

Contact Us

The plastic paper cup on the interior wall is also an eco-friendly paper cup with an inner plastic coating that can be filled with both cold and hot beverages.

-

Contact Us

Cold and hot beverages can be filled, and high-definition printing is supported for displaying personalised artwork and brand logos.

-

Contact Us

8 fluorescent colors, colors superimposed naturally, vibrant colors, non-toxic, smooth writing, thick/thin line switching

-

Contact Us

The PCS standard tower parking system features an automatic lifting and rotating device with intuitive navigation. It eliminates the need for drivers to reverse, offering convenient car access.

-

Add to cart

Cras luctus ultricies ex luctus malesuada. Fusce imperdiet interdum consectetur. Pellentesque dignissim sapien semper consequat sollicitudin. Phasellus iaculis libero ac placerat aliquam. Etiam a velit eu diam consequat vestibulum. Ut a malesuada nulla. Vivamus quis maximus nisi, vel molestie sapien. Nunc pharetra finibus elit sed consectetur.

-

Contact Us

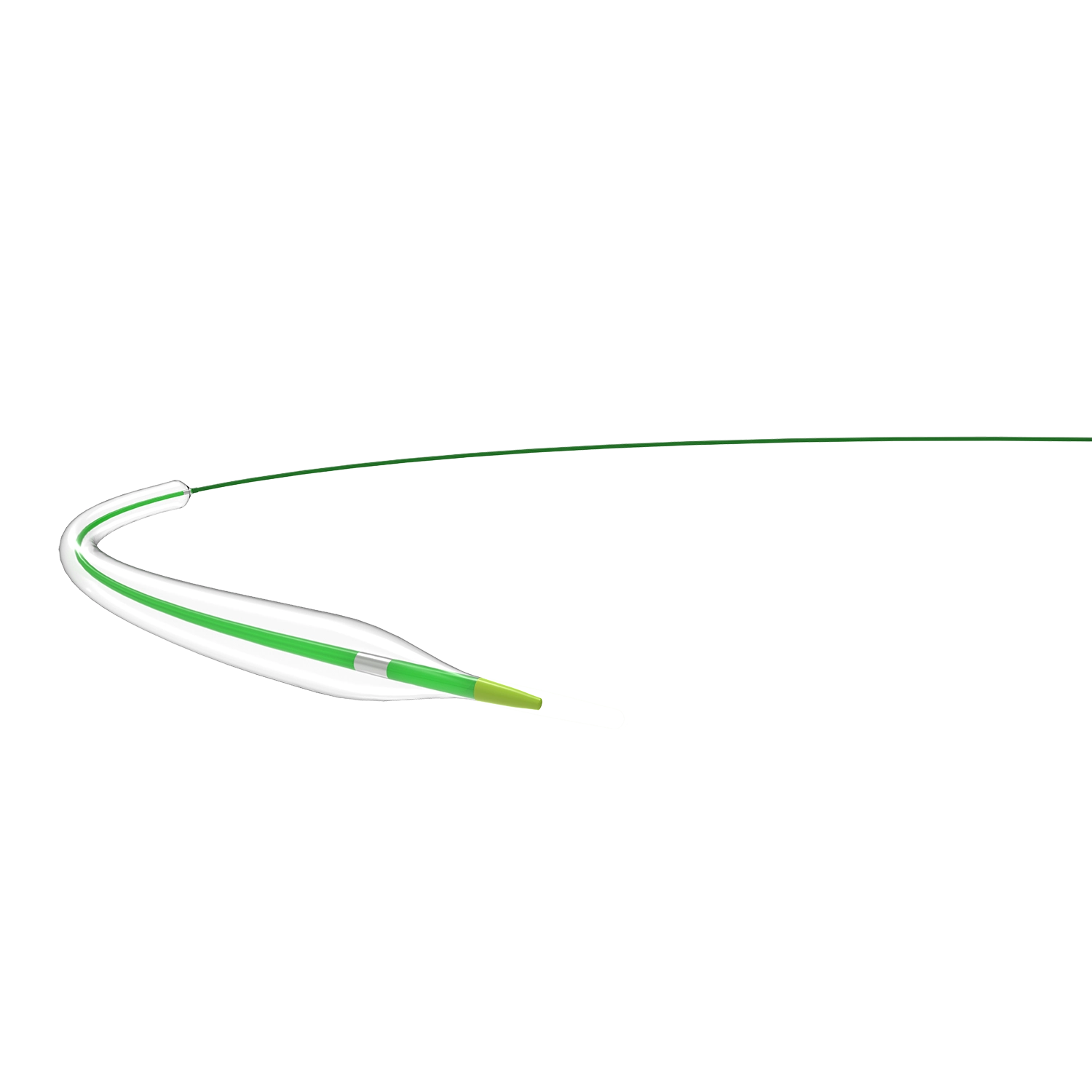

Peripheral Vascular Solutions is a product and service area focused on the treatment of peripheral vascular diseases.

-

Contact Us

PET bottle flakes in the process of recycling has strict requirements on the viscosity and color of the granules, through years of hard search, steady accumulation…

-

Contact Us

WS-501 has high transparency, high shrinkage characteristics, is easy to process,has excellent printability, and has the ability to fit highly complex shapes.

-

Add to cart

Morbi mattis ipsum sem, in gravida dolor venenatis vestibulum. Aenean laoreet, nisi in bibendum dictum, purus libero accumsan enim, id vehicula enim metus vitae ipsum. Maecenas nulla est, dictum quis augue ultrices, dictum rutrum enim. Aliquam erat volutpat.

-

Phasellus varius turpis

Original price was: 87.00$.76.00$Current price is: 76.00$.Add to cartFusce nec diam et dolor ornare rhoncus nec ut mauris. In eleifend mi in felis dictum fermentum. Morbi vel arcu sit amet dolor venenatis bibendum in eu dui. Nulla velit dolor, imperdiet consectetur luctus ut, faucibus eget est.