Hot Dip Galvanized Wire Machine

Products Galvanizing Wire: Low ,medium and high carbon steel wire Diameter range: 0.7mm~8.0mm As clients requirement Coating Zinc weight range: 40~100g/m2,150~450g/m2

Hot Dip Galvanized Wire Machine

Products: Low ,medium and high carbon steel wire

Diameter range: 0.7~1.6mm,0.7~8.0mm,1.6~4.0mm,5.0~8.0mm According to client requirement

Coat weight range: 40~100 g/m2 ,150~450g/m2

Quantity of Wires: 6 lines,10 lines,16 lines,20 lines ,24 lines ,30 lines,36 lines,40 lines,50 lines,60 lines According to client requirement

DV: 20~150

Product Capacity: 2,000~60,000tons/year

Example :

Hot-dip galvanizing design scheme for Low carbon steel wire

Technical Agreement for Heat Treatment Hot Dip Galvanized Wire

Technical requirements for production line

Raw Material: low carbon wire,high carbon wire

Size wire: φ0.7-8.0mm

Coating Zinc: 40-400g/m2

Tensile strength: 400-500MPa

Product Capacity: 450ton/month

Annealing furnace: working online with natural gas power

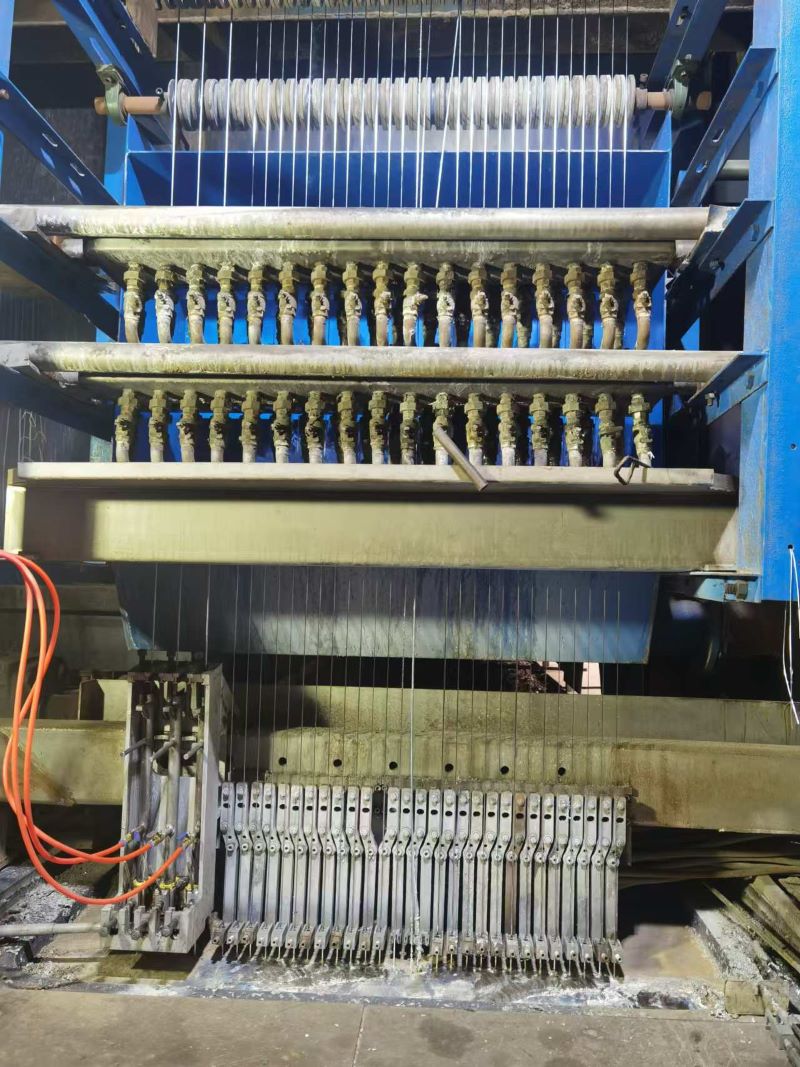

Show Galvanzing Wire Take-Up Machine

Design parameters:

Spacing between two parallel lines: 40±1mm

Height of steel wire working: 900mm

Steel wire inlet type: Straight type

Electrical power: As customers factory example 380V,50Hz

Process flow:

Pay-off passive type for bobbin 800 (10m)→(2)Annealing furnace online(22m) →(3)Air cooling(15m) + water cooling(3m)

→(4)Smokeless acid washing (HCL)(12.5m)→(5)water flushing 3 stages (3.2m)→(6)Auxiliary galvanizing(2m)

→(7)Drying(6m)→(8)Hot Dip Galvanizing(6.5m)→(9)Vertical type coiler collecting(10m)

Show Annealing Furnace :

Fuel used in heat treatment furnace: natural gas.

The front and rear steel wire inlet and outlet of the furnace are equipped with electric switch furnace doors, easy to operate

The furnace uses a high efficiency and energy saving individual blower for air supply, greatly reducing operating costs.Smoke exhaust system: the smoke is discharged from the inlet wire, through the air heat exchanger, furnace pressure electric regulating valve, through the smoke pipe into the steel chimney natural emission

Hydrochloric acid pickling (smokeless pickling)

The total length of the acid tank is 17.5m, and it is equipped with a storage tank and an upper working tank. There are three sections inside the tank, and the acid tank is fully sealed with water curtains at both ends to prevent acid mist from leaking out. Pickling is equipped with electric heating and starts at the beginning of production; During normal production, acid heating can be carried in by the heat brought in by the steel wire, and the temperature of the steel wire entering the acid tank can be controlled by adjusting the cooling water volume

Galvanizing Pot

According to the heating characteristics of the round-bottom round-corner zinc pot, the form of external heating and heating is adopted. The high-speed burner of natural gas is arranged in the diagonal corner of the hot-dip galvanized furnace. The outlet speed of the combustion product of the high-speed burner can reach 120~160m/s.

Wiping Galvanizing Wire System

Asbestos block wipe system

Can be used to produce zinc coated thin steel wire; The wire enters between the two wipes and the liquid zinc is squeezed and falls back to the zinc pool

Nitrogen wipe system

The nitrogen air knife system is designed to have high thickness zinc layers between a wide line speed. Each wire leaves the zinc-aluminum liquid and is protected in a ring by its own nitrogen gas knife

Reviews

There are no reviews yet.