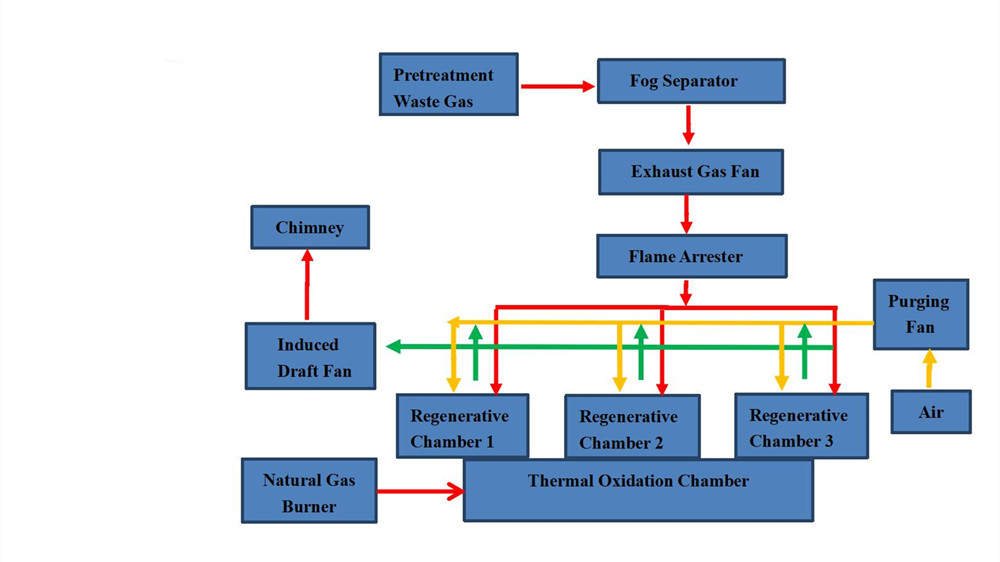

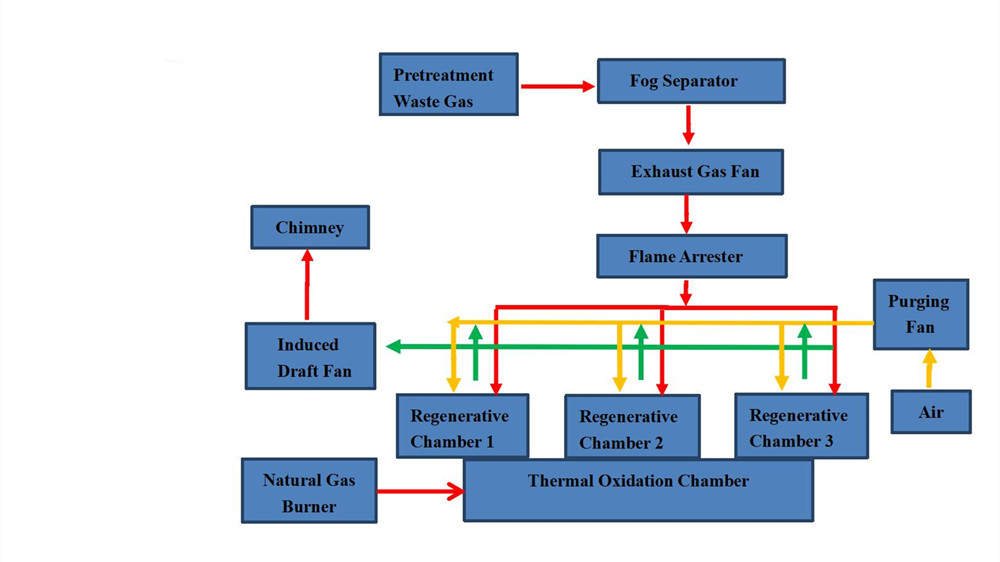

Regenerative thermal incinerator (RTO)

Coating, textile, pharmaceutical, chemical organic waste gas of low concentration, big air volume;

Coating, textile, pharmaceutical, chemical organic waste gas of low concentration, big air volume;

DF-03 is modified starch by inserting hydration groups and high temperature stabilizer to improve the water solubility and temperature resistance (up to 135 ℃). And ensure its good fluid loss performance under both low and high temperature. DF-03 is an environmental friendly, low viscosity, salt resistance (up to saturation) filtration reducer. Its recommend dosage is 1.0%-2.0%.

This project is a 10,000 tons/year hazardous waste incineration device for Ningxia, which is used for incineration and treatment of hazardous waste produced by our factory.

The project plans to build a 60-ton-day hazardous waste incineration device of Jiangxi Brothers Pharmaceutical Co., LTD., for the incineration and treatment of the hazardous waste generated by the plant.

The two-component gel is poured into the liquid seal type HEPA filter , and this is used as an installation seal.

Morbi mattis ipsum sem, in gravida dolor venenatis vestibulum. Aenean laoreet, nisi in bibendum dictum, purus libero accumsan enim, id vehicula enim metus vitae ipsum. Maecenas nulla est, dictum quis augue ultrices, dictum rutrum enim. Aliquam erat volutpat. Quisque ultricies ornare lacus, eu sagittis urna euismod ac. Nulla rhoncus ultrices ligula, id maximus ligula ultricies non.

Reviews

There are no reviews yet.